About Us CONTACT

Telephone:0731-22868219

Fax: 0731-22868219

Email : sales@chinatungstens.com

Contact address: Building 5, 581 Heilongjiang Road, Liyu Industrial Park, Tianyuan District, Zhuzhou City, Hunan Province

Details

Tungsten copper

Classification:

Key words:

Tungsten Copper alloy

90WCu sheet

tungsten switch contact Tungsten copper electrodes

Tungsten copper heat sinks

tungs

E-mailL:

Mobile(whatsapp):

Product Description

Tungsten Copper :

Tungsten-Copper alloy is the composite of Tungsten and Copper, which own the excellent performances of Tungsten and Copper, such as heat-resistant, ablate-resistant, high-intensity, excellent thermal and electrical conductivity. It is easy to be machined. It is used widely in such industries as engine, electrical power, electron, metallurgy, spaceflight and aviation. Using CIP formation, sintered tungsten skeleton and infiltrating copper (silver) technology, large size and special shape products of tungsten-copper (silver) composites with 6-90 percent of copper are produced, such as electric contacts, electrode, refractory parts, heat sinks and parts of rocket, We can also produce sheet material, tubing, plate and other small products by mould pressing, extrusion pressing and MIM.

Main Specifications of W-Cu Composite

|

Type |

Density g/cm3 |

Conductivity %IACS |

HB MPa |

Size mm |

|

WCu50 |

11.9~12.3 |

≥55 |

1130~1180 |

Tube: Ø3~390 |

|

WCu40 |

12.8~13.0 |

≥47 |

≥1375 |

|

|

WCu30 |

13.8~14.4 |

≥42 |

≥1720 |

|

|

WCu20 |

15.2~15.6 |

≥34 |

≥2160 |

|

|

WCu10 |

16.8~17.2 |

≥27 |

≥2550 |

|

|

WCu7 |

17.3~17.8 |

≥26 |

≥2900 |

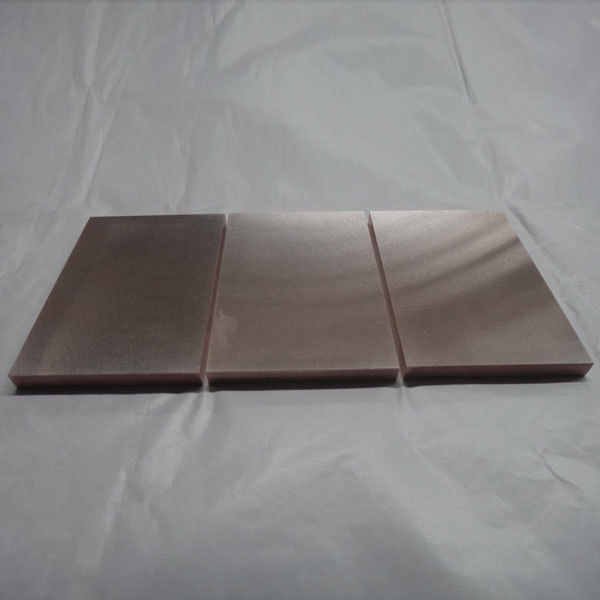

90WCu sheet

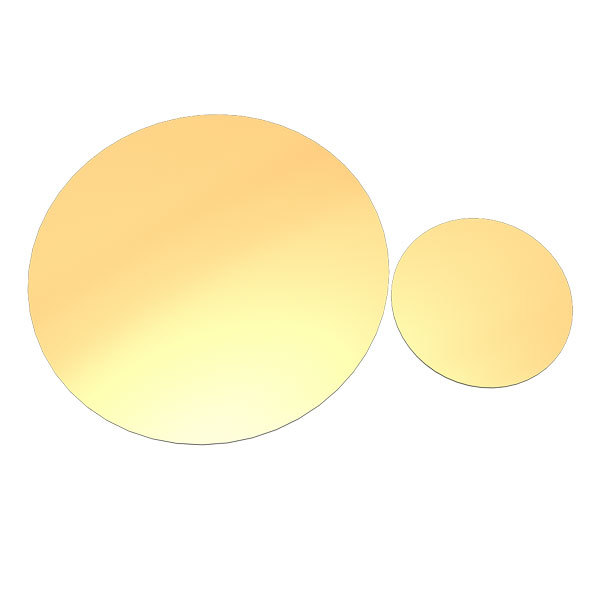

Tungsten copper electrodes Tungsten copper heat sinks

Resistance Welding

The high physical and mechanical properties, as well as the thermal and electrical conductivity, of refractory metal composites make these materials very suitable for die inserts and electrode facings, flash and butt welding dies, and hot upsetting. They can also solve heat balance problems.

| Content | Density g/cm³ | Hardness HRB | Conductivity %IACS | Class | RWMA |

| W50Cu50 | ≥11.9 | ≥65 | ≥54 | ||

| W55Cu45 | ≥12.5 | ≥70 | ≥49 | 10 | 10.7445 |

| W70Cu30 | ≥14.1 | ≥82 | ≥42 | ||

| W75Cu25 | ≥14.5 | ≥90 | ≥38 | 11 | 11.744 |

| W80Cu20 | ≥15.2 | ≥100 | ≥34 | 12 | 12.7435 |

| W85Cu15 | ≥15.9 | ≥240HB | ≥30 | ||

| W90Cu10 | ≥16.75 | ≥260HB | ≥27 |

Heat Sinks

JBNR developed CuW75 to be used extensively in thermal mounting plates, chip carriers, flanges, and frames for high-power electronic devices. As a copper tungsten material, it’s a composite, so both the thermal advantages of copper and the very low expansion characteristics of tungsten can be utilized.

The combination of these two materials results in thermal expansion characteristics similar to those of silicone carbide, aluminum oxide, and beryllium oxide, used as chips and substrates. Because of its thermal conductivity and expansion characteristics, it works well in densely packed circuits.

Typical proprerties Heat Sink of W-Cu

| Material Composition | W-10Cu | W-15Cu | W-20Cu | W-25Cu | W-30Cu |

| Density (g/cm3) | 17.1 | 16.4 | 15.5 | 14.8 | 14.2 |

| TC (W/m·K) | 191 | 198 | 221 | 235 | 247 |

| CTE (×10-6/K) | 6.3 | 7.1 | 7.6 | 8.5 | 9.0 |

Electrical Contacts

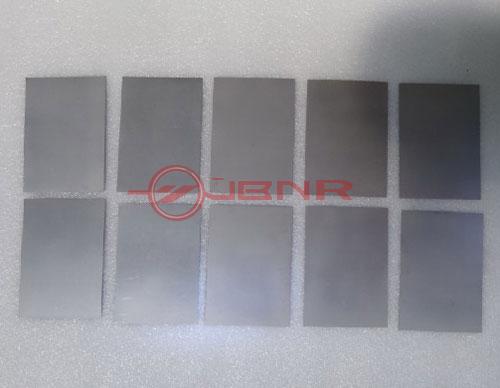

EDM and ECM

tungsten composites are used worldwide for EDM (Electrical Discharge Machining) and ECM (Electrochemical Machining) electrodes. All material is manufactured by the press, sinter, and infiltrate process. Virgin powders are used, resulting in a consistent homogeneous material giving high and even burning rates. Copper tungsten is used in plunger/sinker applications where intricate definition is required, especially in tungsten carbide.

Dimensions

Balls: φ 1.5mm -φ 100mm

Shafts: (φ1mm above)×(Length max.600mm)

Sheets: (Thickness 0.15mm above)×(Wideness max.200mm)×(Length max.500mm)

Square, round and rectangle sizes: diameter 550mm above

According the demanding

Previous Page

Next Page

Previous Page

Next Page

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.