About Us CONTACT

Telephone:0731-22868219

Fax: 0731-22868219

Email : sales@chinatungstens.com

Contact address: Building 5, 581 Heilongjiang Road, Liyu Industrial Park, Tianyuan District, Zhuzhou City, Hunan Province

Details

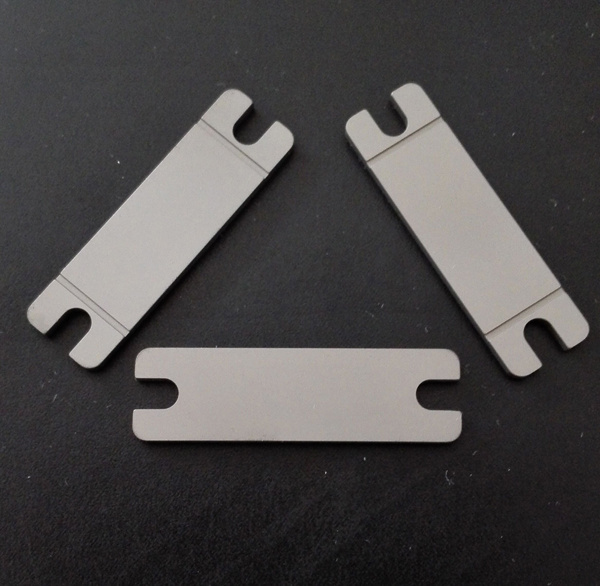

Tungsten Copper(W90Cu10) Heat Sink

Classification:

Key words:

tungsten copper

tungsten copper heat sink

WCu

WCu heat sink

WCu flange

E-mailL:

Mobile(whatsapp):

Product Description

Description:

Tungsten copper heat sink is used for transferring heat generated in microelectronic components to prevent thermal damage.

Tungsten copper heat sink is a composite of tungsten and copper, so both the thermal advantages of copper and the very low expansion characteristics of tungsten can be adjusted to meet different requirements.

The combination of these two materials results in thermal expansion characteristics similar to those of silicone carbide, aluminum oxide, and beryllium oxide, used as chips and substrates.

Advantages:

1. High thermal conductivity

2. Excellent hermeticity

3. Excellent flatness, surface finish, and size control

4. Semi-finished or finished (Ni/Au plated) products available

5. Low porosity

Product Properties:

|

Grade |

W Content |

Density g/cm3 |

Coefficient of thermal Expansion ×10-6 (20℃) |

Thermal conductivity W/(M·K) |

|

90WCu |

90±2% |

17.0 |

6.5 |

180 (25℃) /176 (100℃) |

|

85WCu |

85±2% |

16.4 |

7.2 |

190 (25℃) / 183 (100℃) |

|

80WCu |

80±2% |

15.65 |

8.3 |

200 (25℃) / 197 (100℃) |

|

75WCu |

75±2% |

14.9 |

9.0 |

230 (25℃) / 220 (100℃) |

|

50WCu |

50±2% |

12.2 |

12.5 |

340 (25℃) / 310 (100℃) |

Application:

They are extensively used as thermal mounting plates, chip carriers, tungsten copper flanges, and frames for RF, light emitting diodes and detectors, laser diode packages like pulse, single emitter, bars and complex carriers for optoelectronics amplifiers, receivers, transmitters, tunable lasers, etc.

Previous Page

Next Page

Previous Page

Next Page

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.