About Us CONTACT

Telephone:0731-22868219

Fax: 0731-22868219

Email : sales@chinatungstens.com

Contact address: Building 5, 581 Heilongjiang Road, Liyu Industrial Park, Tianyuan District, Zhuzhou City, Hunan Province

Details

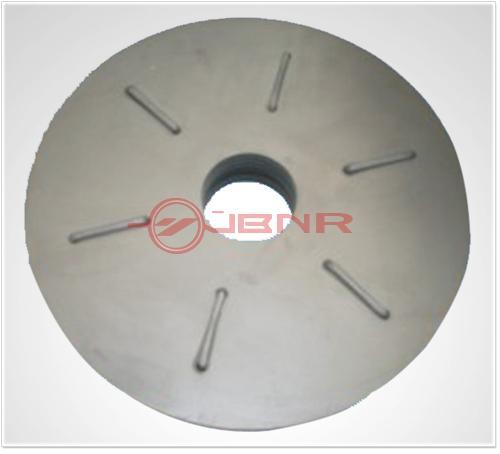

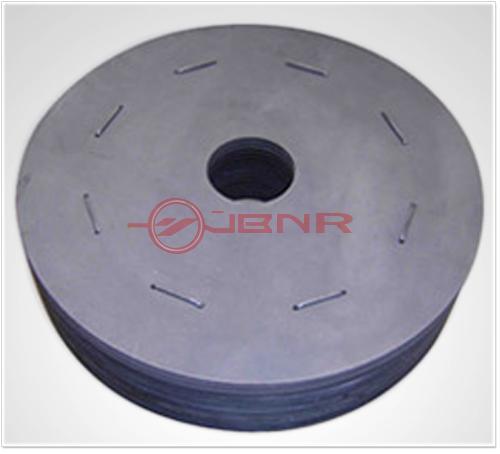

Upper and bottom cover plate

Classification:

Key words:

upper and bottom cover plate

cover plate of heater

heater cover plates

pper and bottom cover plates

heater cover plates

E-mailL:

Mobile(whatsapp):

Product Description

Ⅰ、 Physical and chemical properties

1 Purity:Mo≥99.95%;

W ≥99.95%;

2 Density:Mo≥

W ≥

3 Application temperature environment:≤

Ⅱ、 Measurements and tolerances

Unit:mm

|

Thickness |

Max diameter |

|

2.0±0.1 |

660±0.2 |

|

1.0±0.08 |

660±0.2 |

|

0.5±0.04 |

660±0.2 |

|

0.3±0.03 |

660±0.2 |

Special sizes can be manufactured based on customers' requirements

Ⅲ 、Manufacture process and equipment

| Molybdenum reflection shield | Item | Process | Equipment | Quality check point |

| 1 | Molybdenum sheet or tungsten sheet | 1. Physical and chemical properties 2. Measurements (length, width, thickness) 3. Surface quality | ||

| 2 | Check | |||

| 3 | Wire cutting | Wire cutting machine | 1. Surface cleaness | |

| 4 | Machine | NC milling machine, bench drill, lathe | 2. Tolerances on the drawings | |

| 5 | Clean | 3. No peeling and crack | ||

| 6 | Check | |||

| 7 | Assembly | Assembly platform | 1. Surface cleaness | |

| 8 | Clean | 2. Assembly stability | ||

| 9 | Check | 3. Assembly tolerances | ||

| 10 | Pack | 4. Issue certificate of quality |

Ⅳ、Application

As the heat shield parts in the sapphire growth furnace, molybdenum heat shield, molybdenum upper cover and bottom cover have the key influence on the heat reflection.

High purity, accurate dimenisons, smooth surface, easy assembly, and reasonable design of the molybenum heat insulator will be very important for the sapphire ingot quality.

Previous Page

Next Page

Previous Page

Next Page

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.